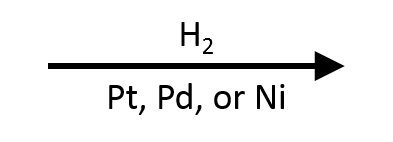

Alkyne Reactions: Catalytic Hydrogenation with H₂ (Pd/Pt)

Alkyne Reactions: Catalytic Hydrogenation with H₂ (Pd/Pt)

Molecular hydrogen delivered over a supported palladium or platinum catalyst (Pd/C, Pt/C, PtO₂) reduces alkynes completely to alkanes. On the metal surface, H₂ splits into M–H species and the alkyne binds through its π system to the same face. Two syn surface deliveries follow the Horiuti–Polanyi sequence: the first converts the adsorbed alkyne into a cis-alkene still anchored to the catalyst, and the second adds from that face again to release the alkane. Under unpoisoned Pd/Pt, the second step is rapid, so the alkene intermediate is not isolated. To stop at the cis-alkene, poison the catalyst (Lindlar, Pd/BaSO₄ or Pd/CaCO₃ with quinoline or lead modifiers); to obtain trans-alkenes, switch to dissolving-metal reduction (Na/NH₃(l), covered separately).

This guide uses ethynylcyclohexane as the mechanism showcase and walks through practical shortcuts, selectivity warnings, and a single worked example you can mirror with the Reaction Solver.

Quick Summary

- Reagents/conditions: H₂ (balloon to autoclave pressures) with Pd/C, Pt/C, or PtO₂ in EtOH, EtOAc, AcOH, or hexanes; room temperature to reflux.

- Outcome (Pd/Pt): Two syn surface additions reduce each C≡C to a C–C single bond (alkane).

- Partial stop: Lindlar (poisoned Pd) furnishes the cis-alkene selectively; unpoisoned Pd/Pt races to the alkane.

- Stereochemistry: Each surface hydrogenation delivers syn addition; the cis-alkene intermediate remains bound unless the catalyst is poisoned.

- Side chemistry: Pd/Ni catalysts can hydrogenolyze benzylic/allylic protections and reduce nitro or azide groups; adjust protecting-group strategy.

Mechanism (6 Surface Steps)

Class: Heterogeneous, closed-shell Horiuti–Polanyi sequence on a Pd/Pt surface. Illustrations generated with ethynylcyclohexane.

The metal surface splits H₂ into adjacent hydrides. The ethynylcyclohexane remains in solution while the surface loads up with syn-deliverable hydrogen equivalents.

Ethynylcyclohexane coordinates through the triple bond, flattening onto the Pd/Pt face. A surface hydride migrates to the proximal carbon, converting the adsorbed alkyne into a cis-alkene that is still anchored to the catalyst.

The remaining surface hydride attacks from the same face, giving the fully saturated C–C bond. On an unpoisoned catalyst, this step is fast and prevents isolation of the alkene.

Ethylcyclohexane leaves the surface, regenerating vacant sites. If the catalyst is intentionally poisoned (Lindlar), this desorption competes effectively with the second addition, releasing the cis-alkene instead.

The vacant metal ensemble immediately binds another equivalent of H₂. Dissociative adsorption regenerates the paired surface hydrides required for the next syn delivery.

With hydrides in place, a new alkyne can adsorb and repeat the Horiuti–Polanyi sequence. Continuous turnover hinges on this rapid reactivation of the surface.

Mechanistic Checklist

- Two syn additions on the same metal face drive C≡C → alkane under standard Pd/Pt.

- The cis-alkene exists as a surface intermediate; it is released only when the catalyst is poisoned.

- No rearrangements occur; adsorption orientation controls regioselectivity.

- Surface hydrides deliver closed-shell electron flow (no radicals or carbocations in solution).

- Selectivity hinges on catalyst choice: Lindlar for cis-alkenes, dissolving-metal reduction (Na/NH₃(l)) for trans-alkenes.

- Beware hydrogenolysis of benzyl/allyl groups and reduction of nitro or azide moieties on Pd/Ni surfaces.

Worked Example

Example A — Internal alkyne → alkane

Teaching point: Two syn additions occur in rapid succession; the cis-alkene never leaves the surface when Pd/C is unpoisoned.

Multiple Unsaturations & Selectivity

- Alkynes bind the surface strongly and typically hydrogenate before isolated alkenes present in the same molecule or mixture.

- With excess H₂ and unpoisoned Pd/Pt, expect global saturation of accessible C=C and C≡C sites.

- To isolate a cis-alkene, select Lindlar (Pd/BaSO₄ or Pd/CaCO₃ with quinoline) or related partially poisoned catalysts.

- For trans-alkenes, choose dissolving-metal reduction (Na/NH₃(l)); standard Pd/Pt cannot deliver the E-alkene.

Practical Tips & Pitfalls

- Catalyst handling: Pd/C and Pt/C are pyrophoric when dry—store wet, filter carefully, and quench spent catalyst under inert or aqueous conditions.

- Gas delivery: Provide vigorous stirring and a steady H₂ source (balloon, bubbler, or pressure reactor) to avoid mass-transfer limits.

- Selectivity control: Do not rely on limiting H₂ to stop at an alkene; poisoning the surface is the reliable strategy.

- Functional groups: Watch for hydrogenolysis of benzyl/allyl protections, reduction of nitro or azide groups, and potential halide hydrogenolysis.

- Solvent choice: Alcohols (EtOH), esters (EtOAc), or acetic acid are common media; avoid unintended poisons unless partial reduction is desired.

Exam-Style Summary

H₂ over Pd or Pt reduces alkynes to alkanes via two syn additions on the metal surface (Horiuti–Polanyi). The cis-alkene intermediate is only isolable with a poisoned catalyst such as Lindlar; otherwise the reaction proceeds directly to the alkane. No rearrangements occur, but sensitive protecting groups may hydrogenolyze.

Interactive Toolbox

- Mechanism Solver — recreate the ethynylcyclohexane sequence frame by frame.

- Reaction Solver — predict hydrogenation outcomes for your own substrates.

- IUPAC Namer — verify systematic names for substrates and products.

FAQ / Notes

Why is each addition syn? Both hydrogens originate from the same metal face; surface delivery enforces syn addition for each step.

Can I stop at the alkene by limiting H₂ with Pd/C? Generally no. The second syn delivery is fast on unpoisoned catalysts, so switch to Lindlar or another poisoned system for cis-alkenes.

Will aromatic rings reduce under these conditions? Mild Pd/Pt at balloon pressure leaves arenes intact, but harsh Ni or high-pressure systems can hydrogenate aromatic rings.

What about stereochemistry in the starting alkyne? Internal stereogenic centers survive; the only new stereochemical element arises from the syn/syn addition across the former triple bond.